Anodized aluminum is, simply, aluminum that has undergone a process to create a highly-durable finish. To create anodized aluminum, the metal is immersed in a series of tanks where it undergoes an electrochemical process and an anodic layer is grown from the metal itself. Read More…

At Tompkins Metal Finishing, we offer mid to high volume aluminum anodizing. We do pre-cleaning, etching, deoxidizng, dyeing and sealing. We can achieve a wide range of surface finishes from bright to dull matte in clear, black, gold, blue and red. Other methods are also available with consideration of alloy, coating thickness, masking requirements and racking instructions.

Pioneer offers many custom finishing solutions to make your products perform at the highest levels. We are experts in providing specialized finishes to improve the performance for your specific component parts. Whether your product design requirements include finishes to make your product resist corrosion, last longer, look better, slide more freely, bond securely to another material, or many...

At All Metals Processing of Orange County, we specialize in providing high-quality aluminum anodizing services that enhance both the performance and appearance of metal components. We take pride in our ability to deliver precise, consistent finishes that improve corrosion resistance, durability, and aesthetic appeal across a wide range of applications.

At Automatic Anodizing, we specialize in providing high-quality aluminum anodizing services designed to enhance both the appearance and performance of aluminum parts. With decades of experience, we have built a reputation for precision, consistency, and reliability in every project we handle. Our advanced anodizing processes improve corrosion resistance, wear protection, and surface hardness...

Dajcor Aluminum is the leading Canadian supplier of extruded, fabricated/machined and anodized components and assemblies to the automotive, renewable energy, transportation, building trades, military, recreation, and consumer-product industries.

More Anodized Aluminum Manufacturers

What is Anodized Aluminum?

Anodized aluminum refers to aluminum that has undergone a controlled electrochemical process to create a highly durable, corrosion-resistant, and decorative oxide finish. The anodizing process transforms the surface of raw aluminum, building up an anodic layer that is integral to the metal itself. Unlike paint or powder coatings, which are applied onto the surface and can chip, flake, or peel, the anodized layer is formed from the aluminum substrate and will not detach or degrade under normal use conditions.

This protective anodic oxide layer enhances the natural properties of aluminum, making it one of the most resilient and long-lasting metal finishes available. Compared to alternative metals such as copper or stainless steel, anodized aluminum is up to 60% lighter and three times harder than untreated aluminum, offering an impressive combination of strength and reduced weight. These advantages make anodized aluminum a superior choice for applications that demand durability, aesthetics, and low maintenance.

Are you wondering, “How does the anodizing process work and what makes anodized aluminum different from other finishes?” The following sections explain the unique properties, manufacturing methods, and wide-ranging uses of anodized aluminum—helping you make informed decisions when selecting materials for your projects or products.

What Makes Anodized-Aluminum Coil Unique?

Anodized-aluminum coil is produced through a continuous coil anodizing process, which involves unwinding large rolls of aluminum and passing them through a series of treatment tanks. These tanks perform key steps including cleaning, coloring, anodizing, and sealing, before the finished aluminum is rewound into a coil, ready for fabrication or shipment.

The coil anodizing process offers significant advantages over traditional batch anodizing. Since the aluminum is processed in a continuous coil, it delivers exceptional consistency in color, thickness, and finish across large quantities of material. This is critical for industries such as architecture, automotive, and electronics, where uniform appearance and performance are essential. Furthermore, coil anodized aluminum is available in a wide array of colors and finishes, tailored to meet precise client specifications, whether for exterior cladding, signage, or consumer products.

Unlike the batch anodizing method—which requires each individual aluminum part to be electrically connected via metal hooks or racks, often leaving unsightly burn marks and increasing waste—the coil process eliminates these inefficiencies. This reduces production costs, minimizes surface defects, and improves material utilization. In addition, coil anodized aluminum can be supplied in large, continuous lengths, simplifying downstream fabrication and reducing installation time.

Looking for cost-effective, high-performance, and visually consistent aluminum materials? Coil anodized aluminum is an ideal solution for manufacturers and designers who require lightweight, durable, and aesthetically versatile options for their projects.

What are the Benefits of Anodized Aluminum?

The unique characteristics of anodized aluminum set it apart from other metal finishes. Whether you are sourcing materials for architectural projects, transportation components, or consumer products, understanding the key benefits of anodized aluminum can guide your material selection process.

1. Superior Durability and Corrosion Resistance

Aluminum is naturally resistant to corrosion, but the anodization process exponentially enhances its protective qualities. The resulting anodic layer is chemically bonded to the aluminum, creating a surface that is three times harder than untreated aluminum and highly resistant to scratching, abrasion, and wear. This robust surface finish will not chip, flake, or peel, even under harsh environmental conditions. Additionally, anodized aluminum will not rust, tarnish, or weather, thanks to the controlled oxidation process. This makes it a preferred choice for both indoor and outdoor applications where long-term durability is essential.

- Excellent resistance to UV radiation and fading

- Non-reactive surface for food service, medical, and laboratory uses

- Low maintenance requirements—easy to clean and keep looking new

2. Extensive Custom Color and Finish Options

One of the standout features of anodized aluminum is its ability to accept a wide range of colors and finishes. Before the anodized surface is sealed, its porous structure allows for the infusion of dyes or metallic salts, enabling manufacturers to match virtually any brand color or Pantone® swatch. This adaptability extends to mimicking the appearance of premium metals such as gold, bronze, copper, stainless steel, and brass—offering the visual appeal of these materials without their susceptibility to corrosion and high weight.

Looking for UV-stable, fade-resistant, and vibrant colors? Anodized aluminum delivers long-lasting color stability, even in outdoor or high-traffic environments. Weathered, patina, or brushed finishes are also available for those seeking unique textures or aged appearances. Importantly, the color is locked into the anodic layer, ensuring it will not chip, peel, or flake over the entire lifespan of the product.

- Custom colors for branding or design requirements

- Range of textures, including matte, satin, and gloss finishes

- Consistent appearance across large surface areas

3. Lightweight Yet Strong

One of the key reasons anodized aluminum is so widely used across diverse industries is its exceptional strength-to-weight ratio. Weighing approximately 60% less than stainless steel, copper, or brass, anodized aluminum offers significant savings in shipping costs and structural load requirements. This lightweight property, combined with its superior toughness, makes it an optimal choice for applications where weight reduction is critical—such as aerospace, automotive, and portable consumer electronics.

- Reduced transportation and installation costs

- Improved energy efficiency in vehicles and buildings

- Enhanced design flexibility for lightweight structures

4. Environmentally Friendly and Sustainable

Anodized aluminum is a sustainable material choice for eco-conscious projects. The anodizing process produces minimal hazardous byproducts, and the finished product is fully recyclable without loss of properties. Additionally, anodized surfaces do not emit volatile organic compounds (VOCs) and require less frequent replacement or maintenance compared to painted or coated metals.

- 100% recyclable and reusable

- Low environmental impact during production

- Complies with LEED and green building standards

5. Enhanced Aesthetics and Design Versatility

From architectural facades to high-end consumer electronics, anodized aluminum is prized for its modern, sophisticated appearance. The anodic layer can be engineered for different surface qualities—from matte to mirror-like finishes—enabling designers to achieve their creative vision without compromising on function. Its tactile qualities also make it suitable for touchpoints, such as elevator panels, appliance housings, and luxury packaging.

Where is Anodized Aluminum Used? Major Applications and Industry Use Cases

Anodized aluminum’s unique blend of durability, light weight, and customizable aesthetics makes it a sought-after material across a wide range of industries. Curious about where anodized aluminum is most commonly specified? Explore the following applications and see how this versatile material can benefit your next project:

- Architectural Panels and Building Facades

- Exterior and interior cladding, curtain walls, and column covers

- Window frames, door frames, and storefronts

- Sunshades, canopies, and decorative elements

- Transportation and Automotive Components

- Aircraft interiors, rail car panels, marine hardware

- Automotive trim, emblems, and body panels

- Consumer Electronics and Appliances

- Laptop casings, smartphones, tablets, and audio equipment

- Kitchen appliances—microwaves, coffee makers, refrigerators

- Signage and Displays

- Retail signage, point-of-sale displays, and exhibition stands

- Industrial Equipment and Machinery

- Protective housings, control panels, and machine covers

- Art, Furniture, and Luxury Goods

- Custom furniture, lighting fixtures, and fine art installations

Architecture

Because aluminum does not rust and requires little maintenance, anodized aluminum is a premier choice for exterior building applications. It is commonly used for architectural paneling, window and door frames, roofing systems, and outdoor furniture. Designers and architects appreciate its ability to deliver a contemporary aesthetic—whether through metallic sheens, custom colors, or weathered finishes—while offering superior protection against sun, moisture, and pollution.

For interior spaces, anodized aluminum elevates the look of ceiling panels, wall cladding, elevator panels, and retail fixtures. Its customizable finishes allow for seamless integration with corporate branding and interior design themes. Are you comparing anodized aluminum to stainless steel or painted metals for your next building project? The combination of color stability, resistance to wear, and ease of fabrication makes anodized aluminum a cost-effective and visually appealing solution.

Transportation

Durability and weight reduction are paramount in the transportation industry. Anodized aluminum meets these needs by providing a strong, lightweight material that resists corrosion from road salts, de-icing chemicals, and extreme weather. It is widely used for:

- Aircraft interiors and galley components—offering both fire resistance and aesthetic appeal

- Rail car panels, bus frames, and marine applications where exposure to moisture is constant

- Automotive parts, including trim, grilles, and decorative panels, thanks to its scratch resistance and color stability

Are you seeking ways to reduce weight and fuel consumption in your transportation designs? Anodized aluminum offers the perfect blend of performance and efficiency.

Consumer Goods

Modern consumers demand products that are both stylish and durable. Anodized aluminum fulfills these requirements in household appliances, cookware, electronics, and lifestyle accessories. Its smooth, easy-to-clean surface resists fingerprints and stains, while the variety of available colors and textures enhances product differentiation. Manufacturers of high-end kitchen appliances, coffee makers, audio equipment, and even smart devices choose anodized aluminum for its premium look and tactile quality.

Wondering how anodized aluminum can make your product line stand out? The environmentally friendly anodizing process produces materials with outstanding longevity, dynamic beauty, and unmatched durability, elevating both brand value and customer satisfaction.

Industrial and Technical Applications

Industrial sectors rely on anodized aluminum for protective enclosures, machine covers, and control panels. The non-conductive properties (when properly sealed) make it suitable for electrical and electronic housings. Its resistance to chemical exposure and abrasion further broadens its use in laboratory equipment, medical devices, and food processing machinery.

If you are conducting a material comparison for industrial projects or technical components, consider anodized aluminum for its low maintenance, corrosion resistance, and customizable performance features.

How to Choose the Right Anodized Aluminum Supplier

Selecting the ideal anodized aluminum supplier is a critical decision that impacts product quality, project timelines, and overall costs. Here are the most important criteria and decision factors to consider when evaluating anodized aluminum manufacturers:

- Technical Capabilities: Does the supplier offer coil and batch anodizing? Can they deliver custom colors, thicknesses, or finishes to match your project requirements?

- Quality Control: Are there robust quality assurance processes in place to ensure consistent finish, color, and performance?

- Lead Times and Availability: How quickly can they deliver anodized aluminum coils, sheets, or custom components?

- Certifications and Compliance: Does the supplier meet ISO, RoHS, REACH, or LEED certifications? Are materials compliant with relevant standards?

- Customer Support and Communication: Is there a dedicated support team to assist with technical queries, prototyping, and after-sales service?

- Sustainability: Are the supplier’s processes environmentally friendly? Do they use recycled materials or renewable energy?

To ensure the best outcome when purchasing anodized aluminum, it is recommended to compare at least four companies using our curated list of Anodized Aluminum manufacturers. Each manufacturer profile highlights their areas of expertise, capabilities, and includes a contact form for information requests or quote submissions. Utilize our proprietary website previewer to review each company’s offerings, and streamline supplier outreach with our convenient RFQ form—enabling you to contact multiple anodized aluminum companies simultaneously.

Ready to start your search? Request quotes from leading anodized aluminum suppliers today and compare technical capabilities, pricing, and turnaround times to find the perfect match for your project’s needs.

Frequently Asked Questions About Anodized Aluminum

- How is anodized aluminum different from powder-coated or painted aluminum?

Anodized aluminum features an oxide layer that is grown from the metal itself, making it integral and more durable than surface coatings like powder coat or paint, which can chip or peel. - What are the color options for anodized aluminum?

Virtually any color can be achieved, from vibrant hues to metallic tones, with excellent UV stability and long-lasting performance. - Is anodized aluminum suitable for outdoor use?

Yes, anodized aluminum is highly resistant to sunlight, moisture, and pollution, making it ideal for exterior applications. - Can anodized aluminum be recycled?

Absolutely. Anodized aluminum is fully recyclable, contributing to sustainable manufacturing and green building initiatives. - How do I maintain anodized aluminum surfaces?

Simple cleaning with mild soap and water is typically sufficient to maintain the appearance of anodized aluminum products. - What is the typical lead time for custom anodized aluminum orders?

Lead times vary depending on finish, quantity, and supplier—request quotes from multiple manufacturers for accurate timelines.

Conclusion: Why Choose Anodized Aluminum?

Anodized aluminum offers a rare combination of attributes—exceptional durability, lightweight design, versatile aesthetics, and sustainability—that make it a top choice for today’s architects, manufacturers, engineers, and product designers. Whether you are seeking a high-performance, low-maintenance solution for building exteriors, a premium finish for consumer electronics, or an environmentally responsible material for your next project, anodized aluminum delivers unmatched value.

Still have questions about anodized aluminum applications, benefits, or supplier selection? Contact our experts for personalized advice and discover how anodized aluminum can elevate your next project.

Aluminum Anodizing

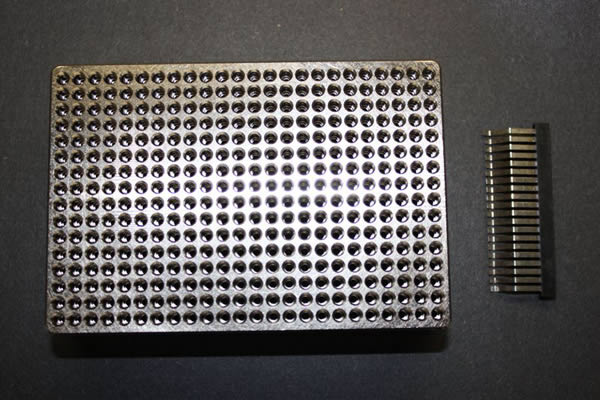

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services