Clear anodizing is typically a sulfuric acid anodizing process, and as a result, offers better wear resistance than chromic acid anodizing and comparable corrosion resistance. Used in a variety of applications, clear anodizing benefits diverse industries including: architecture, for use in window and door frames, railings and siding; automotive, for use in trim and housings for various exposed parts; printing, for use as commercial photolithography plates; and industrial manufacturing, for sheet metal and various extrusions such as profiles and cases for additional surface protection. Read More…

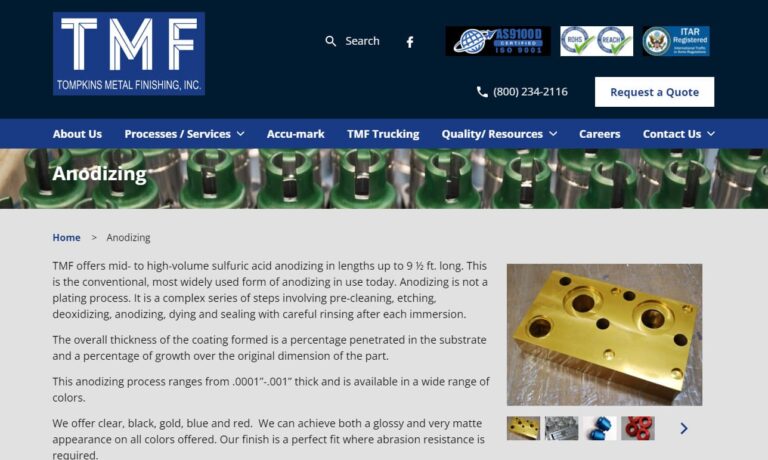

At Tompkins Metal Finishing, we offer mid to high volume aluminum anodizing. We do pre-cleaning, etching, deoxidizng, dyeing and sealing. We can achieve a wide range of surface finishes from bright to dull matte in clear, black, gold, blue and red. Other methods are also available with consideration of alloy, coating thickness, masking requirements and racking instructions.

Pioneer offers many custom finishing solutions to make your products perform at the highest levels. We are experts in providing specialized finishes to improve the performance for your specific component parts. Whether your product design requirements include finishes to make your product resist corrosion, last longer, look better, slide more freely, bond securely to another material, or many...

At All Metals Processing of Orange County, we specialize in providing high-quality aluminum anodizing services that enhance both the performance and appearance of metal components. We take pride in our ability to deliver precise, consistent finishes that improve corrosion resistance, durability, and aesthetic appeal across a wide range of applications.

At Automatic Anodizing, we specialize in providing high-quality aluminum anodizing services designed to enhance both the appearance and performance of aluminum parts. With decades of experience, we have built a reputation for precision, consistency, and reliability in every project we handle. Our advanced anodizing processes improve corrosion resistance, wear protection, and surface hardness...

Dajcor Aluminum is the leading Canadian supplier of extruded, fabricated/machined and anodized components and assemblies to the automotive, renewable energy, transportation, building trades, military, recreation, and consumer-product industries.

More Clear Anodizing Manufacturers

Additionally, clear anodizing can be colored by means such as organic dyes and metallic salts to create colors such as red, yellow, blue and green for decorative applications such as jewelry or artwork. Some further benefits of clear anodizing include decreased part maintenance, reduced metal weight, being environmentally-friendly and increased production efficiency.

The clear anodizing process is basically identical to the Type II sulfuric acid anodizing process. A commonly used anodizing process, Type II sulfuric acid requires the metal to be fully immersed into sulfuric acid, a highly corrosive and oil-like acid that is formed from sulfur dioxide. When the metal is immersed in the acid an electric current, generally direct current, is sent through the sulfuric acid and reacts with anodes on the surface of the material. The reaction of the current and the anodes creates the hard outer film of oxidation.

After the material is removed from the sulfuric acid bath, it is then sealed through the use of hot water in order to enhance the corrosion-resistant properties of the film. If a color is going to be added, then the dye or salt must be introduced after immersion in the sulfuric acid bath but before sealing, so that when sealed, the color will become locked in.

While the addition of color can be eye-catching, clear anodizing allows the natural luster of the metal to shine through. Although aluminum is the most common material used in clear anodizing, other metals may be anodized as well including: titanium, magnesium, zinc, niobium and tantalum.

Aluminum Anodizing

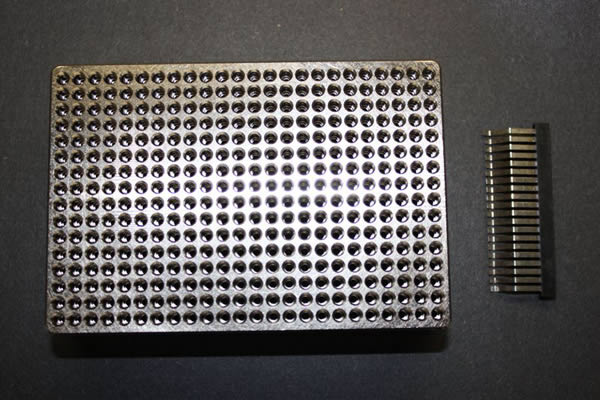

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services