Explore Our Aluminum Anodizing Gallery

Welcome to our Aluminum Anodizing Gallery! Here, you can click on the images below or the menu above to explore a variety of high-performance aluminum anodizing services. Each category showcases cutting-edge anodizing techniques used in diverse industries, ensuring top-quality results for your applications.

Aluminum Anodizing

Aluminum Anodizers

Anodizing Services

Color Anodizing

Overview of Aluminum Anodizing

Aluminum anodizing is a process that increases the thickness of the natural oxide layer on the surface of aluminum parts, enhancing their durability and corrosion resistance. This technique is widely used for both aesthetic purposes and for improving the longevity of aluminum products.

Types of Aluminum Anodizing and Their Applications

There are several types of anodizing techniques, including Type I (chromic acid anodizing), Type II (sulfuric acid anodizing), and Type III (hardcoat anodizing). Each offers unique benefits depending on the desired application, from decorative finishes to heavy-duty industrial uses.

Industries Served by Aluminum Anodizing

Aluminum anodizing is utilized across a broad range of industries, including aerospace, automotive, electronics, and architecture. These industries rely on anodized aluminum to ensure the longevity, appearance, and performance of their products under various environmental conditions.

Benefits of Choosing the Right Aluminum Anodizing Manufacturer

Selecting the right anodizing manufacturer ensures that you receive high-quality, durable finishes tailored to your specific needs. By partnering with experienced suppliers, you can improve product performance, reduce maintenance costs, and achieve superior aesthetic results for your aluminum components.

Discover More Industry-Leading Suppliers

Need more options? Explore IQS Directory to find the most trusted manufacturers and suppliers in the aluminum anodizing industry.

Aluminum Anodizing

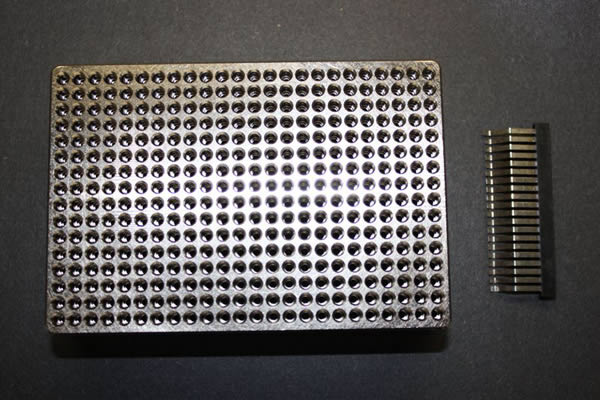

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services