Hard anodizing (also known as hardcoat anodizing) is the process of applying a dense anodic coating of aluminum oxide by converting an aluminum alloy component that has been thoroughly cleaned and deoxidized into an oxide film using an appropriate electrolyte to make it thicker and more abrasion-resistant. Read More…

At Tompkins Metal Finishing, we offer mid to high volume aluminum anodizing. We do pre-cleaning, etching, deoxidizng, dyeing and sealing. We can achieve a wide range of surface finishes from bright to dull matte in clear, black, gold, blue and red. Other methods are also available with consideration of alloy, coating thickness, masking requirements and racking instructions.

Pioneer offers many custom finishing solutions to make your products perform at the highest levels. We are experts in providing specialized finishes to improve the performance for your specific component parts. Whether your product design requirements include finishes to make your product resist corrosion, last longer, look better, slide more freely, bond securely to another material, or many...

At All Metals Processing of Orange County, we specialize in providing high-quality aluminum anodizing services that enhance both the performance and appearance of metal components. We take pride in our ability to deliver precise, consistent finishes that improve corrosion resistance, durability, and aesthetic appeal across a wide range of applications.

At Automatic Anodizing, we specialize in providing high-quality aluminum anodizing services designed to enhance both the appearance and performance of aluminum parts. With decades of experience, we have built a reputation for precision, consistency, and reliability in every project we handle. Our advanced anodizing processes improve corrosion resistance, wear protection, and surface hardness...

Dajcor Aluminum is the leading Canadian supplier of extruded, fabricated/machined and anodized components and assemblies to the automotive, renewable energy, transportation, building trades, military, recreation, and consumer-product industries.

More Hard Anodizing Manufacturers

What is Hard Anodizing?

Hard anodizing—also referred to as hardcoat anodizing or Type III anodizing—is a specialized aluminum surface treatment that transforms the outer layer of aluminum alloy parts into a dense, thick, and highly abrasion-resistant aluminum oxide coating. This process is essential for manufacturers and engineers seeking to improve the durability, corrosion resistance, and wear performance of aluminum components across a wide range of industries.

During the hard anodizing process, the aluminum part is thoroughly cleaned and deoxidized, then immersed in an electrolyte solution—most commonly sulfuric acid cooled to near freezing temperatures. Electrical current at voltages up to 100 volts and current densities between 24-36 amps per square foot is applied, causing a controlled oxidation reaction that forms the hard oxide layer. This layer is significantly thicker and harder than that produced by standard anodizing methods, making it ideal for high-wear or demanding environments.

What Distinguishes Hard Anodizing From Other Anodizing Processes?

When evaluating aluminum anodizing options, it’s important to understand the key differences among the main processes:

- Type I (Chromic Acid Anodizing): Produces a very thin (approximately 0.0001 inches) oxide coating. It's typically used where minimal dimensional change is required and for certain aerospace or military specifications.

- Type II (Sulfuric Acid Anodizing): This is the most common form, generating a coating thickness ranging from 0.0002 to 0.0006 inches. Type II anodizing is highly versatile and is often used for decorative applications, as the coating readily accepts dyes for color anodizing.

- Type III (Hard Anodizing / Hardcoat Anodizing): Creates a much thicker (0.0005 to 0.0030 inches or more), denser, and more abrasion-resistant coating. This process uses a higher concentration of sulfuric acid and lower temperatures, with precisely controlled electrical parameters. The resulting hard anodic layer dramatically increases surface hardness, wear resistance, and corrosion protection, making it suitable for high-performance and industrial parts.

Are you curious about which anodizing process is best for your application? Contact an anodizing expert to discuss your project requirements and receive expert recommendations.

Distinguishing Features and Benefits of Hard Anodized Aluminum

The hard anodizing process delivers several unique advantages that set it apart from conventional metal finishing techniques. Hard anodized aluminum is prized for its combination of mechanical, chemical, and electrical properties that enable superior performance in demanding environments. Key benefits include:

- Exceptional abrasion and wear resistance: The hard anodic layer greatly extends component lifespan in high-friction or contact environments, outperforming untreated aluminum and even many steel alloys.

- Improved corrosion resistance: The dense oxide layer acts as an effective barrier, protecting the underlying aluminum from oxidation, pitting, and chemical attack—even in harsh, marine, or corrosive atmospheres.

- Enhanced hardness and durability: Hardcoat anodized surfaces can achieve hardness values up to 500 HV (Vickers), making them highly resistant to scratches, dents, and mechanical damage.

- Superior dielectric properties: The non-conductive oxide coating serves as an electrical insulator, making hard anodized aluminum ideal for electronic housings, insulation plates, and electrical applications where dielectric strength is critical.

- Attractive and customizable appearance: Hard anodizing restores and enhances the visual appeal of aluminum, allowing for decorative finishes—most notably, a rich black color—though other colors can be achieved with proper process controls and dye selection.

- Improved lubricity: The micro-porous structure of hard anodized coatings can retain lubricants, reducing friction and wear in moving assemblies such as pistons, gears, and sliding components.

- Biocompatibility and sterilization: The inert, non-toxic surface is easy to sterilize, making it suitable for medical instruments, food contact surfaces, and laboratory equipment.

- Environmentally friendly: Hard anodizing is a safe, low-emission process that produces no hazardous byproducts, making it a sustainable choice for manufacturers seeking to meet environmental regulations.

Looking for ways to extend the life of your aluminum parts? Explore hard anodizing solutions and discover how this process can add value to your products.

Anodization Class Levels and Impact on Color

When specifying anodized aluminum finishes, understanding the relationship between coating thickness, dye absorption, and color appearance is essential. The class of anodization—Class 1 (undyed) or Class 2 (dyed)—determines how the final color is achieved and how it will appear across different aluminum alloys and thicknesses.

- Class 1 (Undyed) Hard Anodizing: Results in a natural metallic appearance that varies by alloy and oxide thickness. Certain alloys (such as 6xxx series) may exhibit a deep gray-black or bronze-gray tone, while others (2xxx or 7xxx series) may present a lighter gray or bronze shade.

- Class 2 (Dyed) Hard Anodizing: Allows for the introduction of color, most commonly black. Due to the dark tone of the undyed oxide, black is the most popular and uniform result. Other colors are possible but may appear uneven or less vibrant, especially at higher thicknesses. For critical applications, sample panels are recommended when specifying non-black dyes.

Wondering how hard anodizing will affect the color and appearance of your aluminum parts? Learn more about color anodizing options and request a sample to ensure your finish meets aesthetic and functional requirements.

Impact of Hard Anodizing on Part Dimensions and Tolerances

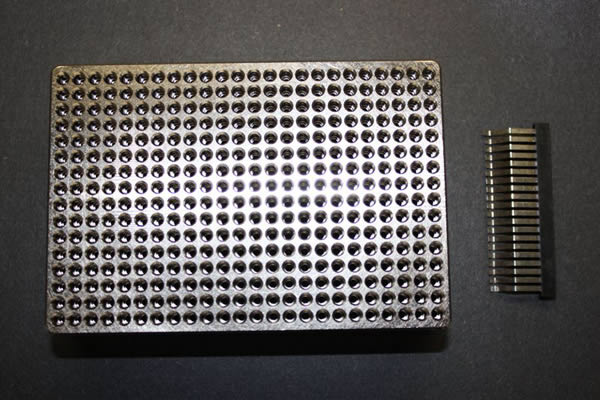

One crucial consideration when choosing hard anodizing is its effect on the dimensions and tolerances of finished parts. Unlike paint or plating, the anodic coating grows both inward (penetrating the aluminum substrate) and outward (adding to the surface). Typically, about half the total coating thickness penetrates the base metal, and the other half builds up on the surface.

For example, a 0.002" (2 mil) hard anodized coating will usually increase each surface’s dimension by approximately 0.001". When tight tolerances are required, it’s essential to factor this dimensional change into the original part design or machining specifications. Consultation with your anodizing supplier can help ensure critical dimensions are achieved after processing.

Need guidance on designing for hard anodized aluminum? Ask: “How will hard anodizing impact my part’s final dimensions and fit?” or “What allowances should I make for coating thickness on precision components?”

Creating Anodized-Free Zones in Hard-Anodized Aluminum

In many applications—especially in electrical engineering and precision manufacturing—there is a need to keep certain areas of a part free from anodizing to maintain electrical conductivity or close fits. Since all anodic coatings act as insulators, masking techniques are commonly used to produce anodize-free zones:

- Rubber plugs for holes and cavities

- 3D-printed silicone stop-offs for complex geometries

- Custom die-cut decals or tapes for flat surfaces

- Painted-on lacquers applied by hand or robotic systems

Effective masking ensures that only the desired surfaces receive the hard anodic coating, preserving critical electrical contacts or precise fits. For intricate or high-volume parts, discuss masking strategies with your anodizer early in the design process.

Do you need electrical contact points or tight tolerances on your anodized aluminum part? Ask: “What masking solutions are available for my application?” or “How do I specify non-anodized areas for my design?”

Sealing of Hard Anodized Aluminum

The final step in the hard anodizing process is often the sealing of the porous oxide layer. Sealing closes the microscopic pores in the anodic film, enhancing corrosion resistance and dye retention, but it may slightly reduce the coating’s hardness and wear resistance. The choice to seal or leave the hardcoat unsealed depends on the intended application:

- Unsealed hard anodizing: Preferred for maximum wear or abrasion resistance (e.g., in sliding, rotating, or mechanical parts). This is the default for most industrial specifications where friction and durability are paramount.

- Sealed hard anodizing: Required when corrosion protection or colorfastness is the primary goal (such as in marine, architectural, or cosmetic applications). Sealing methods include hot deionized water, sodium dichromate, nickel acetate, PTFE (polytetrafluoroethylene), or combinations thereof. PTFE sealing provides some additional lubricity and is used in high-performance contexts.

When specifying your finish, always clarify your primary requirements—whether that’s abrasion resistance, corrosion protection, or both—to ensure the correct sealing protocol is applied.

Ask: “Should I specify sealed or unsealed hard anodizing for my application?” or “Which sealing method provides the best balance of durability and corrosion resistance for my use case?”

Applications for Hard Anodizing

Hard anodized aluminum is a preferred material choice across a wide spectrum of industries thanks to its versatility, reliability, and high-performance properties. Common applications include:

- Valves and valve bodies: For fluid management systems requiring chemical resistance and long-term wear performance.

- Pistons and hydraulic components: To reduce friction and extend the life of moving parts in pneumatic and hydraulic cylinders.

- Sliding parts and guide rails: Where low friction and high wear resistance are crucial for smooth, maintenance-free operation.

- Hinge mechanisms and cams: For consistent performance and resistance to galling in repetitive motion assemblies.

- Gears and sprockets: Lightweight yet durable gear solutions for automation, robotics, and power transmission.

- Swivel joints and connectors: For secure, corrosion-resistant connections in aerospace or marine equipment.

- Insulation plates and electronic housings: Leveraging the dielectric properties of hard anodized aluminum for electrical safety.

- Blast shields and protective covers: Where high durability and environmental resistance are required.

- Food processing and medical equipment: Easy-to-clean, sterilizable surfaces that meet regulatory standards.

Searching for hard anodized parts for a specific industrial use? Browse suppliers and request a quote for your custom application.

Key Industries and Market Sectors Benefiting from Hard Anodizing

From aerospace to consumer electronics, hard anodized aluminum is relied upon wherever a combination of lightweight, strength, and durability is required. Some of the primary sectors leveraging hardcoat anodizing include:

- Aerospace and aviation: Aircraft structural components, landing gear, and interior fittings benefit from reduced weight, high wear resistance, and corrosion protection.

- Automation and robotics: Precision machined parts, end effectors, and moving assemblies require reliable performance in continuous duty cycles.

- Automotive and motorsports: Engine parts, suspension components, and decorative trims gain from improved hardness and resistance to road salts and chemicals.

- Electronics and electrical engineering: Enclosures and insulators utilize the dielectric properties of hard anodized aluminum for safety and performance.

- Food manufacturing and processing: Non-toxic, easy-to-sanitize surfaces for mixers, conveyors, and packaging lines.

- General manufacturing and machining: Jigs, fixtures, and tooling plates designed for longevity in repetitive-use environments.

- Hydraulics and pneumatics: Corrosion- and wear-resistant cylinders, pistons, and manifolds.

- Medical devices and laboratory equipment: Biocompatible, sterilizable components for surgical instruments and diagnostic tools.

- Military and defense: High-reliability parts for weapons systems, vehicles, and protective gear.

- Optical and precision instruments: Camera housings, lens mounts, and measurement devices requiring stable, hard surfaces.

- Sporting goods and recreation: Lightweight, durable frames for bicycles, firearms, and outdoor equipment.

Want to know if hard anodized aluminum is right for your industry or product? Ask our specialists for advice on material selection and finishing options.

How to Choose the Right Hard Anodizing Supplier

Selecting a reliable hard anodizing company is crucial to achieving the desired performance and quality for your aluminum parts. Here’s a step-by-step guide to help you evaluate and select the best supplier for your needs:

- Compare multiple hard anodizing suppliers: Use our Hard Anodizing Directory to review business profiles, experience, certifications, and technical capabilities.

- Assess technical expertise: Look for suppliers with a proven track record in your industry and the ability to handle your specific alloys, part geometries, and coating requirements.

- Request samples and technical data: Ask for sample parts, process certifications, and test reports to verify coating thickness, hardness, and quality.

- Check turnaround time and capacity: Ensure the supplier can meet your delivery schedules and handle production volumes, from prototypes to large-scale runs.

- Evaluate value-added services: Some suppliers offer additional services such as masking, racking, inspection, and logistics, which can streamline your project.

- Request multiple quotes: Use our streamlined RFQ form to contact several suppliers simultaneously and compare pricing, lead times, and technical support.

Ready to get started? Find and contact hard anodizing companies to discuss your project and request a customized quote today.

Frequently Asked Questions About Hard Anodizing

- What is the typical hardness of hard anodized aluminum? Hard anodized coatings can reach up to 500-600 HV (Vickers hardness), depending on the alloy and process conditions.

- Can hard anodized parts be welded or machined? It’s best to perform welding or machining before anodizing, as the hard oxide layer is difficult to cut or remove and may be damaged by localized heating.

- How does hard anodizing compare to other surface treatments? Hard anodizing offers superior wear and corrosion resistance compared to painting, powder coating, or basic anodizing, and adds minimal weight.

- Is hard anodized aluminum safe for food contact? Yes, when properly sealed and processed, hard anodized aluminum is non-toxic, inert, and safe for cookware and food processing equipment.

- What alloys are best suited for hard anodizing? 5xxx, 6xxx, and 7xxx series aluminum alloys typically respond well to hard anodizing, but results vary by composition. Some casting alloys may have lower coating quality.

- Can I specify a particular color for hard anodized parts? Black is the most uniform and reliable color for hard anodized coatings; other colors may be possible but can be inconsistent at higher thicknesses. Always review color samples prior to production.

Get Started with Hard Anodizing—Request a Quote or Consultation

If you’re ready to enhance the performance, durability, and appearance of your aluminum components, hard anodizing is a proven solution. Our extensive network of qualified hard anodizing companies can help you select the right process, ensure optimal results, and deliver on time and on budget.

Start your search for hard anodizing suppliers or contact our experts for a personalized consultation on your project requirements. Whether you need prototypes, production runs, or technical advice, we’re here to help you achieve the best results with hard anodized aluminum.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services